Integrated Electronic CADCSiEDA

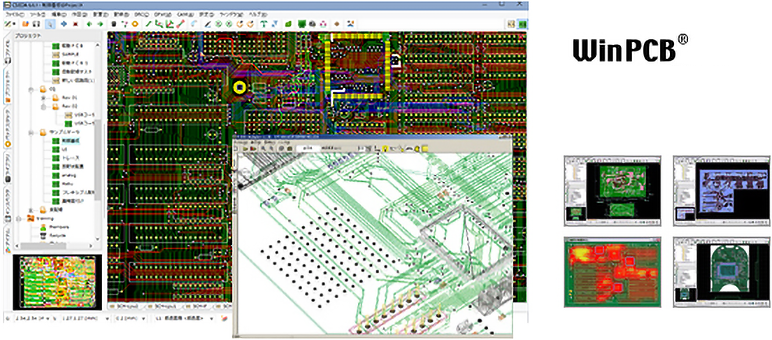

WinPCB

PRINTED CIRCUIT BOARD DESIGN TOOL

Our tool features a wide range of capabilities to support the design of everything

from analog/power/flexible circuit boards to multilayer circuit boards.

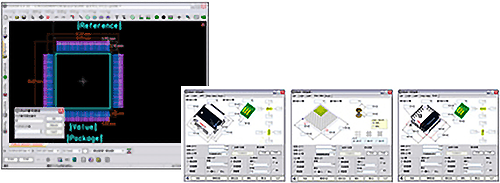

[Parts] Automatic generation of symbol shapes

Package builder

Easily create symbol shapes for DIP, SOP, QEP, BGA, and PLCC by simply entering numerical values, eliminating the need for complicated symbol creation.

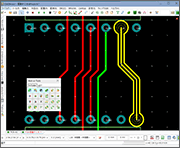

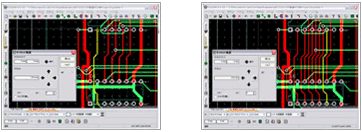

[Wirings] A variety of wiring functions.

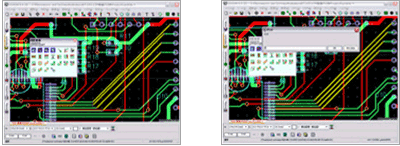

Shape processing box

"Minimize the number of clicks" and "simplify complex processes".

Based on feedback from designers, we have incorporated shape processing box functionality to support these requests.

By simply clicking on various icons, users can execute a wide range of functions, resulting in a further reduction in design time.

Wiring alignment pitch adjustment function

First click: Select the wire you want to shield.

Second click: Select the [Wire Shield] button.

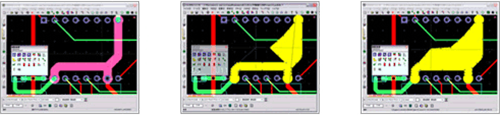

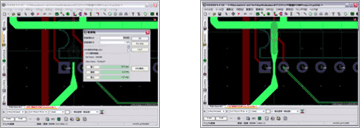

Copper pour feature

First click: Select the wire you want to create a copper pour for.

Second click: Click the "copper pour" button.

Third click: You can now freely modify the copper pour.

Wiring Alignment Pitch Function

First click: Select the wire to be aligned.

Second click: Select the [Align Pitch] button and enter the desired pitch to be changed.

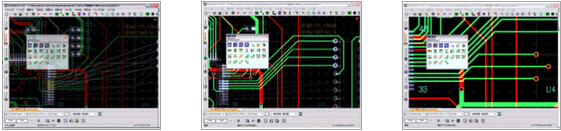

Parallel wiring function

First click: Select the pad where you want to create parallel wiring.

Second click: Click the [Parallel wiring button] and enter the desired pitch.

* You can end parallel wiring with vias (diagonal, straight, downward, upward) while in the process.

Object snap (wire pulling-in) function

Even if the wiring and pad grids are misaligned, the wiring can be snapped to the pad.

Wiring pitch function

First click: Select "[T-branch wiring]" during wiring.

Second click: Enter the starting and ending line widths.

Offset function

First click: Select the wiring to be continuously copied.

Second click: Select the [Offset wiring] and enter the pitch and number of copies to be made.

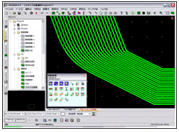

Wire Bundle

First click: Select [Bundled wiring] .

Second click: Enter the number of wires and pitch for the wiring

* You can choose between arc mode, c-cut, and straight.

Build-up wiring

Support for various designs with build-up wiring such as motherboards.

Various Functions

Copper pour feature

First click: Select the pad you want to convert to a clinch pad.

Second click: Select [Customize Pad], and enter the values.

* Supports clinch, rounded corner, breadboard, and tear drop shapes.

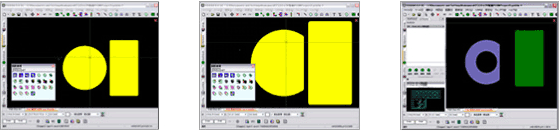

Custom Pad Creation Function

First click: Select the circular or square copper plane for the pad you want to create a land cut for.

Second click: Choose the [Copper Feature] option and perform a copper cut to create the desired shape.

Third click: Change the copper feature to a pad with the desired land cut shape.

Automatic copper pour and floating copper removal function

First click: Select the copper feature where you want to remove automatic or floating copper pour.

Second click: Select the option for [automatic copper pour removal] or [floating copper removal]

Drawing creation function

Drawing creation function

You can select the area you want to zoom in on and place a magnified drawing.

Drawing creation function

Net density information, Component density information, Component heat generation information, Wiring density information, Component height information, Component current value information, VIA density information, Component weight information.

Restoration from Gerber data

Gerber in

You can load not only data output from WinPCB but also Gerber data output from other companies.

* After importing Gerber into WinGerber, convert the data to WGG file and input it into WinPCB.

Diverse verification functions considering PCB manufacturing

※

※

Printed Circuit Board Design Verification Tool

Equipped with DFM/DFE verification functions. Includes DRC function and electrical characteristics check taking into account the manufacturing of printed circuit boards.

Integration with PollEx starts from CSiEDA Ver.6.

EMI/EMC measures (noise reduction measures)

EMI Suppression Design Support Tool

Signal Verification by Circuit Design

Automatic Advice System

CSiEDA is an integrated electronic CAD system that supports the entire process of electronic circuit design. It is capable of total design from circuit design to PCB design/electromechanical design. We provide various simulations for high-quality PCB design in addition to shortening the design process. WinPCB offers high functionality for digital/analog design.

With the recent trend of miniaturization, high density, and high-layer PCBs, CSiEDA enables designers to achieve their intended designs with trimming, shape division, automatic placement, automatic shielding, and build-up board support. In addition, the split design function allows designers to divide design tasks and shorten delivery times. When transitioning from other CAD systems, existing design data can be utilized by converting ASC/Gerber data to WinPCB.

OVERVIEW

Menu customization

Icon customization

Macro function using Java and VB script

Backup function (file number and time settings available)

Zoom in/zoom out/fit to screen/full screen display

Zoom in/zoom out using scroll button

SQL database support

Component/drawing converter for Ver.4.0

Design in millimeters/mils

Print preview/offset function

Arbitrary movement of origin

Virtual origin

Undo/Redo (MAX=20)

DXF input/output support

Support for split design

Filter function (selectable by attribute values such as line width)

Move and arrange components with Enter key

Operation cancel and selection mode with ESC key

Expandable to 1,024 layers

Layer lock function

Conversation layer display

Pair layer display

Customizable display

Direct 3DView display

Various CAD I/F (data, drawing, netlist)

Trace function

Fill/outline display

OLE

Menu usage/unused, display/hidden settings available

Inspector function (change item properties (database))

CREATING COMPONENTS

Extension of the pad stack function (up to 1,024 layers)

Users can register their created pads in the pad stack

Support for inner layer thermal (45/90 degrees), clearance, and land creation

Automatic/manual updating of pad numbers

Functionality for creating pads using JavaScript

Component creation wizard

Offset copy/move function

Support for restricted wiring areas

Support for restricted via areas

Support for copper forbidden area

Support for component height areas

Support for copy/paste functionality

Pad rotation angle specification

Drawing rotation angle specification

Trimming

Shape division

Setting of reference name/attribute size

Double-sided reference name placement

Changing the origin position of the text size

Setting of text pitch

PCB CREATION

Moving components at the center or at pin 1

Support for moving items using the keyboard arrow keys

Alternate specification support for components on the component side/solder side

Support for moving/deleting component pads

Add Pad Functionality to Component

Add Pads

Add Test Points

Attribute changes (individual/batch)

Cutting component silk screen

Component class settings

Component mounting type settings

Component changes (individual/batch)

Offset placement

Matrix placement

Radial placement

Component locking

Component list

Editing component silk screen

PLACEMENT

Improvement of wiring editing

Wiring loop check

Wiring movement

Wiring offset movement

Wiring line exchange

Taper wiring function

Parallel wiring function

Wiring pitch width specification function

Wiring highlighting display

Angular wiring function

Wiring copy function

Wiring offset copy function

Trapezoidal wiring function

Net name ON/OFF

Pad number display ON/OFF

Wiring length setting

Tear drop wiring

Automatic wiring

Semi-automatic wiring

IVH via

Build-up board

Pad-on-via

3D realistic display design

Net addition

Net swap

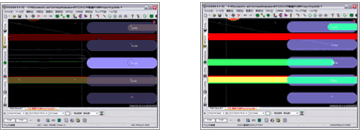

Net color coding

Division of the same net

Editing net name

Net deletion (individual/batch)

Net display ON/OFF

Support for start angle specification of wiring corner (e.g., 45-degree corner starting position)

Support for 45/90-degree thermal wiring

Direct copper conversion function for wiring

BOARD OUTLINE

PCB outline creation function from DXF data

Line offset function

Rounding corners function for PCB

Auxiliary line function

Offset copy/move function

Trimming function

Command-line input (absolute/relative)

COPPER

Offset function for copper (inner/outer)

Function to combine copper shapes

Copper extraction function

Function to specify cutouts in copper shapes

Trimming of copper shapes

Editing of copper shapes

Transformation of shapes into copper (DXF/Gerber data)

Normal copper shapes

Copper cutout shapes

Auto copper shapes

Function to automatically remove floating copper shapes

PowerPlane

Internal layer division

SHAPE

Extension of trimming function

Enhancement of drawing functions (direct editing of circles and arcs)

Support for angle specification of shapes and components

Option to create auxiliary lines on a per-layer basis

Option to delete auxiliary lines as needed

Batch trimming

Alignment function

Evenly spaced arrays

Object snap

Internal layer division

DRC

Net check function

DRC inner layer check

Prohibited area for component placement

Prohibited area for vias

Prohibited area for wiring

Prohibited area for copper planes

Prohibited area for component height

Online DRC

DRC design log

Shortest distance measurement

Batch measurement of shortest distance

Wiring angle check

Measurement tool

CAM

274D/274X Gerber compatibility

NC drill output

NC coordinate/tool table separation

Excellon output

NC hole instruction diagram data

Mounting component coordinate output

Surface mounting (compatible with mixed surfaces)

Gerber-in

Board inversion

Board rotation (45, 90, 180 degrees)

Gerber data output (individual, batch)

MATERIALS

Drawing enlargement function

Wiring database report

Via list report

Wiring length report

Pad stack report

Temperature distribution map

Component placement information report

Height component diagram

Site placement distribution diagram

Density distribution map

Netlist output

Assembly drawing creation

Wiring density distribution diagram

Display of pattern outline for inspection

3D mounting diagram

CONTACT US

- +81-6-6377-2451

9:00 - 18:00 (JST) on weekdays. - INQUIRY

Japanese

Japanese